Waste Oil Recycling Plant

When you consider that you need 160 litres of crude oil to produce 2½ litres of high quality lubricating oil but only 4 litres of used oil to produce the same 2½ litres of the same quality oil then it does not make sense to incinerate or otherwise dispose of used oil. The HERING WORP used oil re-refining system has a comparatively small footprint, generates much of its own fuel from the feedstock being processed and with conversion costs as low as US 10 cents per litre can add up to 3 times the sales value of the oil, once processed. These features combined with the comparatively low investment costs of this type of waste oil re-refining system and the high quality of the output base oils make the WORP from HERING VPT an excellent solution for your re-refining needs.

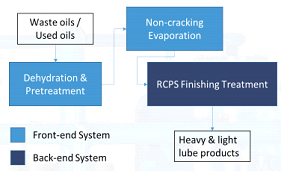

Non-Cracking Evaporator (NCE) technology converts waste oil into high value base oils

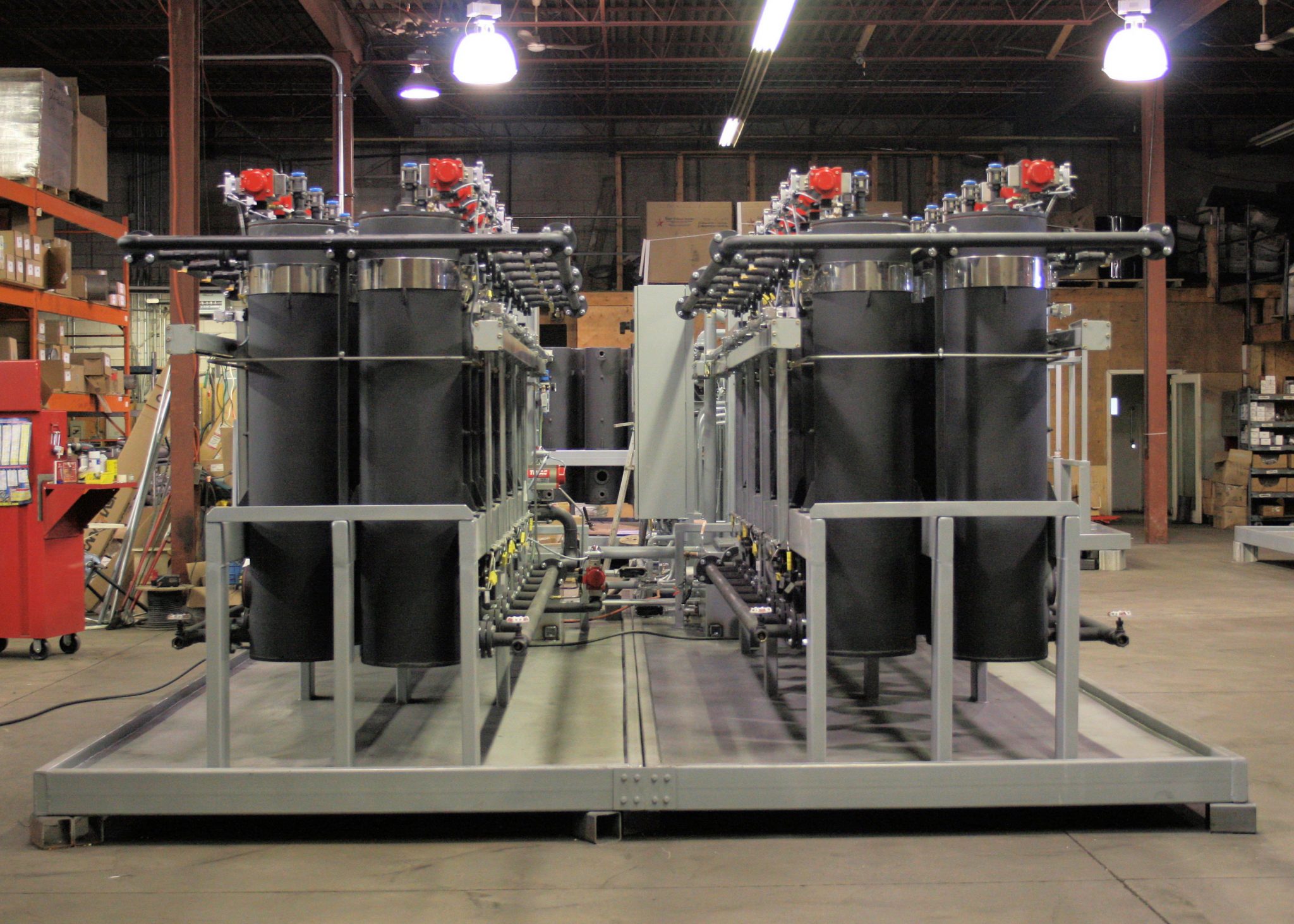

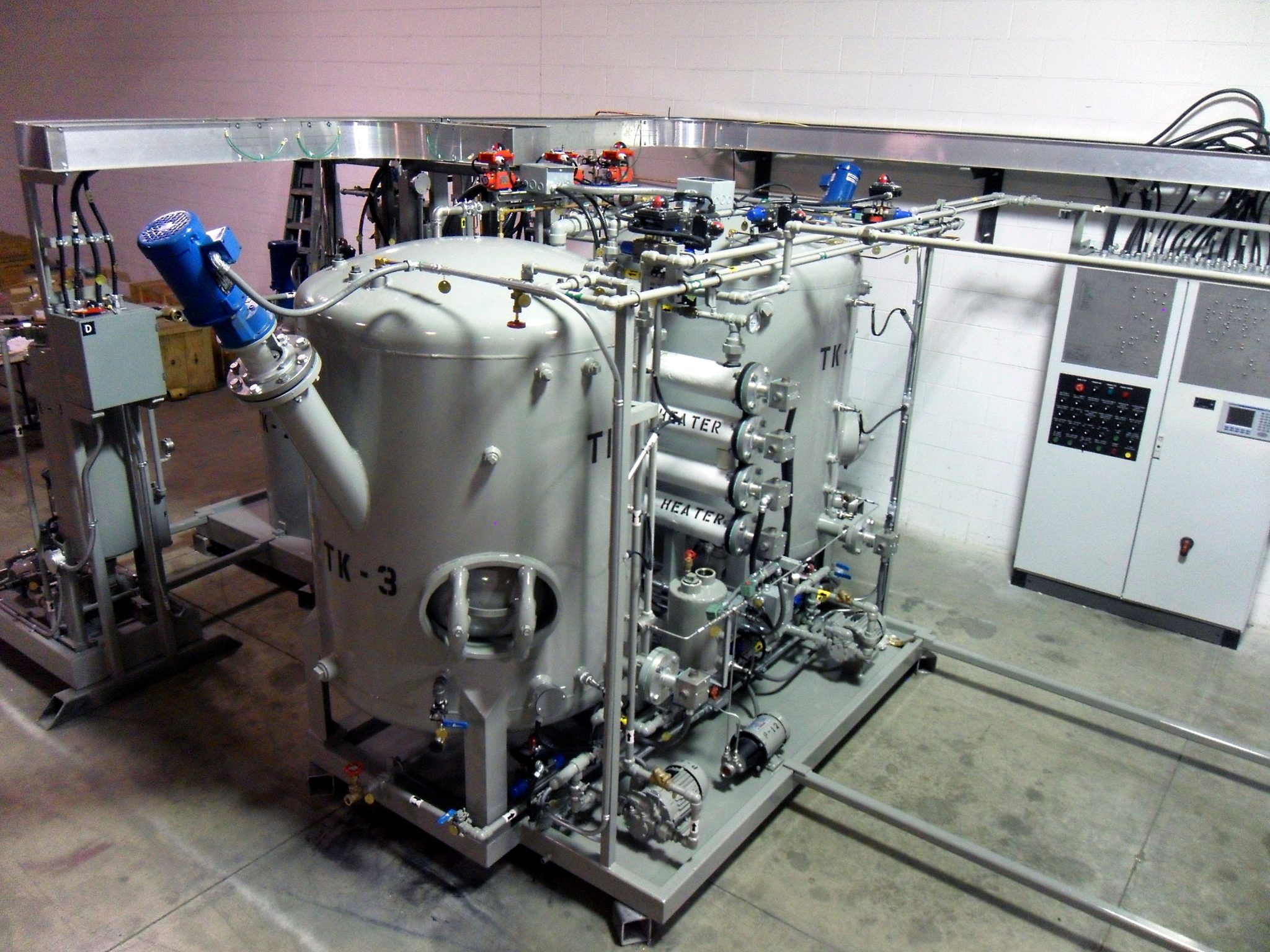

The WORP waste oil recycling plant from HERING VPT can run with any type of used lube oils as input – including, but not limited to, used engine oils, used spindle oils, waste turbine lube oils. After flash evaporating water and light ends from the waste oil, the residual hydrocarbon stream is smeared in a thin-film over a large surface area, under vacuum. By lowering the boiling point of the oil fractions, as they are subject to high vacuum, a number of cuts can be efficiently and economically separated and condensed, typically producing one medium viscosity base oil (~300N) or a low viscosity (~100N) and high viscosity (~500N) cut. The residue sludge can be sold as an asphalt extender, further increasing revenue from the processed waste. Base oil yields of 70% to 80% of the feedstock volume are typical, the balance is made up of water, light ends – which provide fuel for the NCE– and asphalt extender.

Further processing of the base oil using a HERING RCPS Reactivation Clay Polishing System or AMPS Adsorbent Mineral Polishing System stabilizes the oil against oxidation and improves odor of group I and group II base oils

The base oil produced by a standard evaporation system will usually darken with time, potentially reducing its resell value. In the HERING WORP Waste Oil Recycling System, the base oil is stabilized and polished to further enhance its properties. The HERING RCPS clay finishing system is the perfect solution for this, and, thus, an essential part of our waste oil recycling plant. Alternatively, if clay based processes are not suitable for your needs, the HERING AMPS adsorbent mineral polishing system is your system of choice. The HERING finishing treatments yield high quality group I & group II base oils while requiring moderate capital investments and producing low amounts of waste that can be directly disposed at a local landfill without pretreatment. This makes our RCPS or AMPS finishing stage of the HERING WORP Waste Oil Recycling Plant an excellent economic & environmental proposition, see our clay based base oil finishing system section or alternatively our mineral based base oil finishing system page for more details. To know more about waste oil refinery plant contact us

HERING VPT offers all levels of technical, engineering and commercial support to specifically tailor a customized WORS waste oil recycling system to your needs

From day 1 HERING supports your organization through its wide-ranging knowledge. We are able to provide full commercial justifications, tailoring essential ROI calculations to your particular case. Together, we will find the right HERING WORP used oil re-refining plant which fits your needs perfectly. As an illustration of the range of HERING WORP used oil recycling plant sizes available, consider the following table. These are broadly considered to be low throughput, medium throughput and high throughput – intermediate flow rates are available, too, of course.

| Throughput | Annual Throughput (MT) | Flow Rate (LPH)(GPH) | Footprint (sqm)* |

|---|---|---|---|

| Low | 2,000 – 3,000 | 250 (65) | 450 |

| Medium | 30,000 – 40,000 | 4,000 (1,100) | 1,250 |

| High | 75,000 – 100,000 | 10,000 (2,600) | 2,000 |

* of NCE and RCPS/AMPS units only. No tanks farms, outbuildings or other civil engineering accoutrements are included

A large transport trucking company might easily generate over 200,000 litres of used oil per month. A Low throughput system could not only provide significant reductions on the lubricating oil bill but, subject to local regulations, could provide diesel fuel for the trucks. An RCPS or AMPS designed for sulphur reduction will easily remove sulphur down to <300 PPM from typical waste engine oils. Medium throughout systems are typically sought after by regional oil recycling companies that wish to supply base oil to blenders (or use their own blending plant), polished and colour enhanced recycled lube minimizes the amount of brightstock needed. High throughput systems are typically used by national recyclers and those organizations with a large collection area. We are one of the best used oil recycling plant manufacturers.

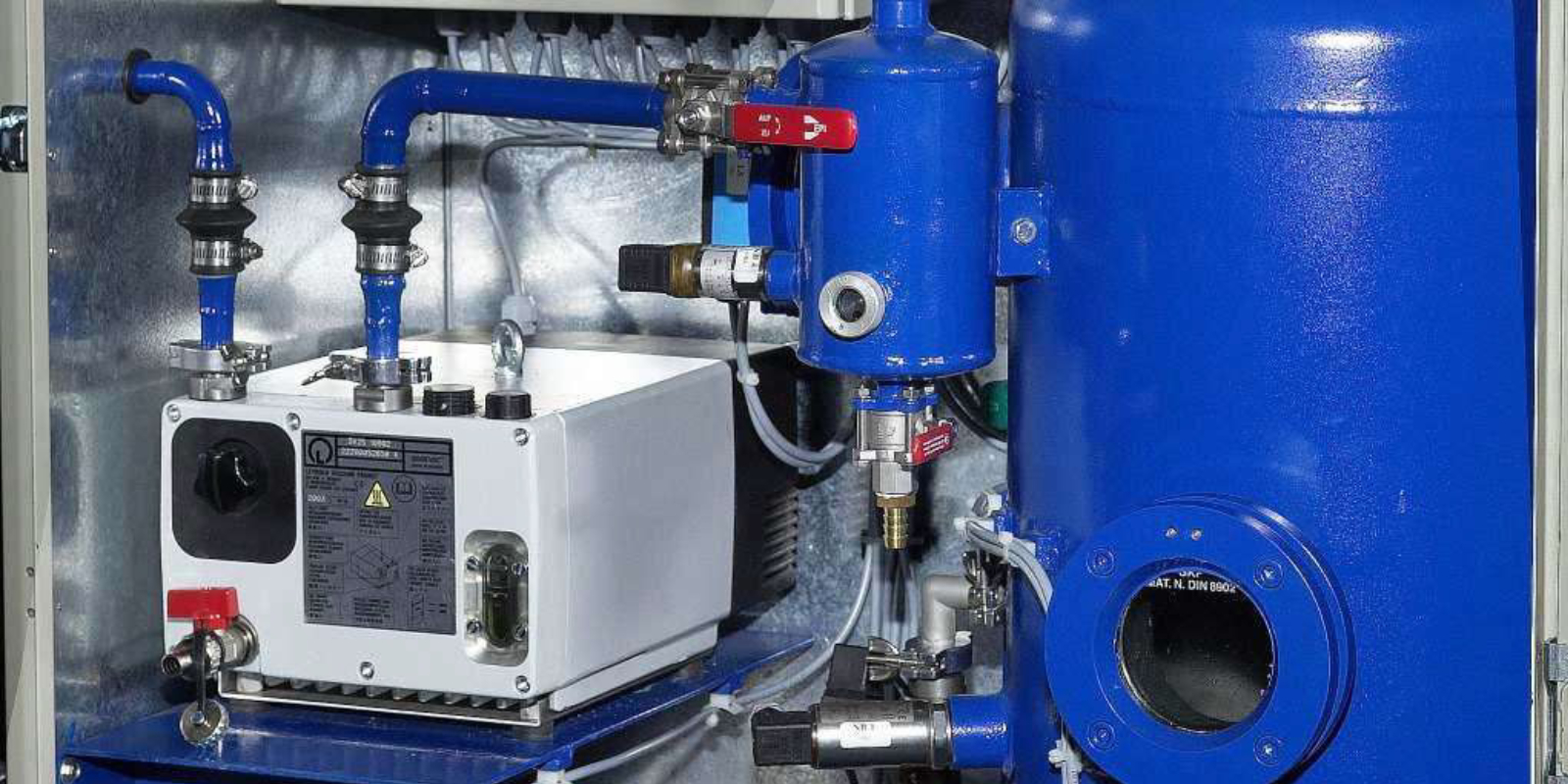

Waste Oil Recycling Plant

Our back-end system, the HERING RCPS® Series reactivation clay polishing unit, improves the waste oil distillates in terms of color, sulfur content and odor and, thus, leads to a valuable output oil product. This finishing treatment uses an adsorption type process to remove any unwanted chemical substances from the treated oil. The RCPS® has the ability to eliminate sulfur from 2000 PPM to less than 300 PPM in a single pass. Processing used oil through our WORP® waste oil re-refining plant results in an oil that is stable against oxidation over any measured timescale and fulfills the highest refining standards of output oils.

The plant will be designed based on the following typical feed characteristics

Input: mixed hydrocarbons containing:

- ~ 3.5% water

- ~ 3.5% light ends [gasoline, aromatics]

- ~ 10% diesel, kerosene

- ~ 68% long-chain hydrocarbons

- ~ 15% residual solids and asphaltenes.

- >~ 3.5% water containing traces [< 2%] of hydrocarbons;

- ~ 13.5% Lights [naphthalene, gasoline, kerosene, diesel]

- ~ 68% longer chain hydrocarbons (100N – 500N)

- ~ 15% asphalt extender [containing solids and asphaltenes]

- Lights (mostly naphthalene, toluene, benzene, xylene, kerosene & diesel)

TEST AND METHODOLOGY VALUE Kinematic viscosity @ 40 °C - ASTM-D445 < 3.3 cSt Cetane 60 – 70 Flash Point - ASTM-D93 < 10 °C Calorific Value > 45 MJ/kg Sulphur - ASTM-D1551 <0.5 % wt. Water - ASTM-D95 < 0.25 % vol. Colour – ASTM-D1500 < 4 Density@ 15 °C - ASTM-D1298 < 0.869 kg/l Carbon residue - ASTM-D189 < 1.0 % wt. Pour point - ASTM-D97 < 15 °C Lead 0 mg/kg Calcium 0 mg/kg Barium 0 mg/kg Zinc 0 mg/kg Iron 0 mg/kg Phosphorus 0 mg/kg Magnesium 0 mg/kg - Medium-chain and long-chain hydrocarbons

TEST AND METHODOLOGY VALUE Ash - ASTM-D482 0.01 % wt. Density @ 15 °C – ASTM-D4052 ~ 0.83 kg/l Water content – ASTM-D95 0.02 % vol. Pour point – ASTM-D97 - 30 °C Colour – ASTM-D1500 < 3 Carbon Conradson Residue – ASTM-D189 < 0.5 % wt. Kinematic viscosity @ 40 °C – ASTM-D445 ~38.0 cSt Sodium < 1 mg/kg Iron < 1 mg/kg Chromium < 0.1 mg/kg Nickel < 0.1 mg/kg Silicon < 0.1 mg/kg Aluminium < 0.1 mg/kg Lead < 0.1 mg/kg Silver 0 mg/kg Copper < 0.1 mg/kg Zinc < 0.1 mg/kgBarium < 0.1 mg/kg Tin < 0.1 mg/kg Sulphur – ASTM-D4294 < 0.2 % wt. Calorific value, Gross 45 MJ/kg Calorific Value, Net 43 MJ/kg Flash Point – closed cup > 210 °C Asphaltenes Content < 0.5% - Industrial Boiler Fuel or Asphalt extender

TEST AND METHODOLOGY VALUE Kinematic viscosity @ 40 °C - ASTM-D445 < 95 cSt Flash Point - ASTM-D93 > 70 °C Calorific Value > 43 MJ/kg Sulphur - ASTM-D1551 Variable Water - ASTM-D95 Lt; 0.1 % vol. Colour Black Density@ 15 °C - ASTM-D1298 > 0.98 kg/l Carbon residue - ASTM-D4530 > 12.0 % wt. Pour point - ASTM-D97 > 18 °C Total acid number – ASTM-D974 0.00 Lead 10 mg - 120 g/kg Calcium 6 – 38 g/kg Barium 20 mg – 16 g/kg Zinc 6 – 15 g/kg Iron 100 mg – 6 g/kg Phosphorus 1 - 6 g/kg Magnesium 350 mg – 5 g/kg Copper 10 mg – 1 g/kg

Output specifications:

From Evaporation Skids:

From Skid WFE Skids:

Product specifications

The Viscosity Index of the lights can be controlled to be anywhere between 50 to 80 and the viscosity at 100°C will be between 2 and 7.5 cSt

Recycling you used oils with the HERING WORP® Series provides you with:

- Low operating costs and initial capital investments compared to other waste oil re-refining processes.

- Flexible operating modes of finishing treatment – Enables adaptation to different input oil qualities. Parallel mode operation is single-pass, fastest processing. Series mode operation simulates triple-pass, better quality oil.

- Modular system ensures flexible layouts while all modules can be shipped inside a 40-foot high cube container

Unattended Oil Polishing Operation of the HERING RCPS® back-end system - Full client involvement during the manufacture, from engineering approval through to start-up.

- All global voltages and frequencies available.

- Low oil losses as part of waste becomes feedstock for front-end system.

- All waste created by WORP® is classified as standard industrial waste leading to low environmental costs.

- Customizable plant sizes – Oil processing capacities ranging from 50 liters per hour for a laboratory setup to 27,000 liters per hour for a re-refinery.

Complete WORP® Waste Oil Re-refining Plant including Front-end and Back-end Systems