Adsorbent Mineral Polishing System

Our HERING AMPS Adsorbent Mineral Polishing System has been created for customers that want a high-performance lube oil polishing treatment without using any chemicals or chemically activated substances, such as conventional bleaching clays. The AMPS re-refined oil polishing system is an ideal post-processing unit for oils that have been pre-treated by vacuum distillation or wipe-film evaporation. The key to the AMPS’ performance and environmental friendliness is the HERING PHÖNIX GREEN highly adsorbent mineral. This naturally occurring mineral has been enhanced by a physical process to lead to highest possible surface areas for maximum thermo-physical efficiency of the lube oil polishing process. HERING PHÖNIX GREEN has been specifically developed to replace conventional bleaching clays. It can be reactivated and reused up to 500 times in our HERING AMPS equipment before needing to be replaced. Our AMPS base oil polishing plant is a low operating cost and environmentally friendly alternative to other chemical re-refined oil polishing methods. The HERING AMPS rewards you with high quality group I and group II base oils.

Lube oil polishing is required to produce high quality lube oils from re-refined oil distillates

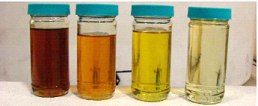

Lube oil re-refining is a highly complex endeavor because waste oils and their high viscosity distillates –as derived during waste oil recycling – have a complex set of interdepending properties which define the quality & price of the final product. Therefore, simple distillation is not enough. You need to use a subsequent lube oil finishing treatment. Flexible lube oil polishing processes are needed to adapt to the independent behavior of the oil distillates and to achieve the best product possible. Such a treatment gets rid of unstable sulfurized and oxidized compounds, odorous components and ash particles. The AMPS lube oil finishing system leads to a clear, light color – finally reaching a water white color depending on the number of passes through our HERING PHÖNIX GREEN. Our systems reach an oil quality that is considered as the highest refining standard.

HERING AMPS Adsorbent Mineral Polishing Systems offer a low capital lube oil finishing treatment to produce group I and group II base oils

Traditionally, there are two groups of lube oil polishing processes: clay based lube oil finishing treatments and catalytic hydro treatments. For many plant operators, hydro finishing incurs too high capital expenses and is potentially too dangerous given the use of hydrogen under high temperatures and extreme pressures. Traditional clay based finishing treatments and the old acid-clay processes require much lower capital investments, but produce a lot of waste which poses an environmental problem as it must be treated by the disposal companies prior to disposal. This has led to these technologies being banned in some countries around the world. Here, our HERING AMPS adsorbent mineral polishing system is the perfect solution to provide you with the best of both worlds without using any chemically activated clay. Our AMPS lube oil finishing systems rely on our 100% natural HERING PHÖNIX GREEN high surface area mineral to enhance your lube oil distillates. The AMPS, thus, yields high quality group I & group II base oils without the usage of any chemicals. The HERING AMPS is environmentally friendly producing only low amounts of waste that can be directly disposed at a local landfill without pretreatment as standard industrial waste. This makes the HERING AMPS lube oil finishing treatment system an excellent economic & environmental proposition for your lube oil polishing needs.

The AMPS’s specially manufactured HERING PHÖNIX GREEN mineral has been physically enhanced for maximum performance – without any chemical additives

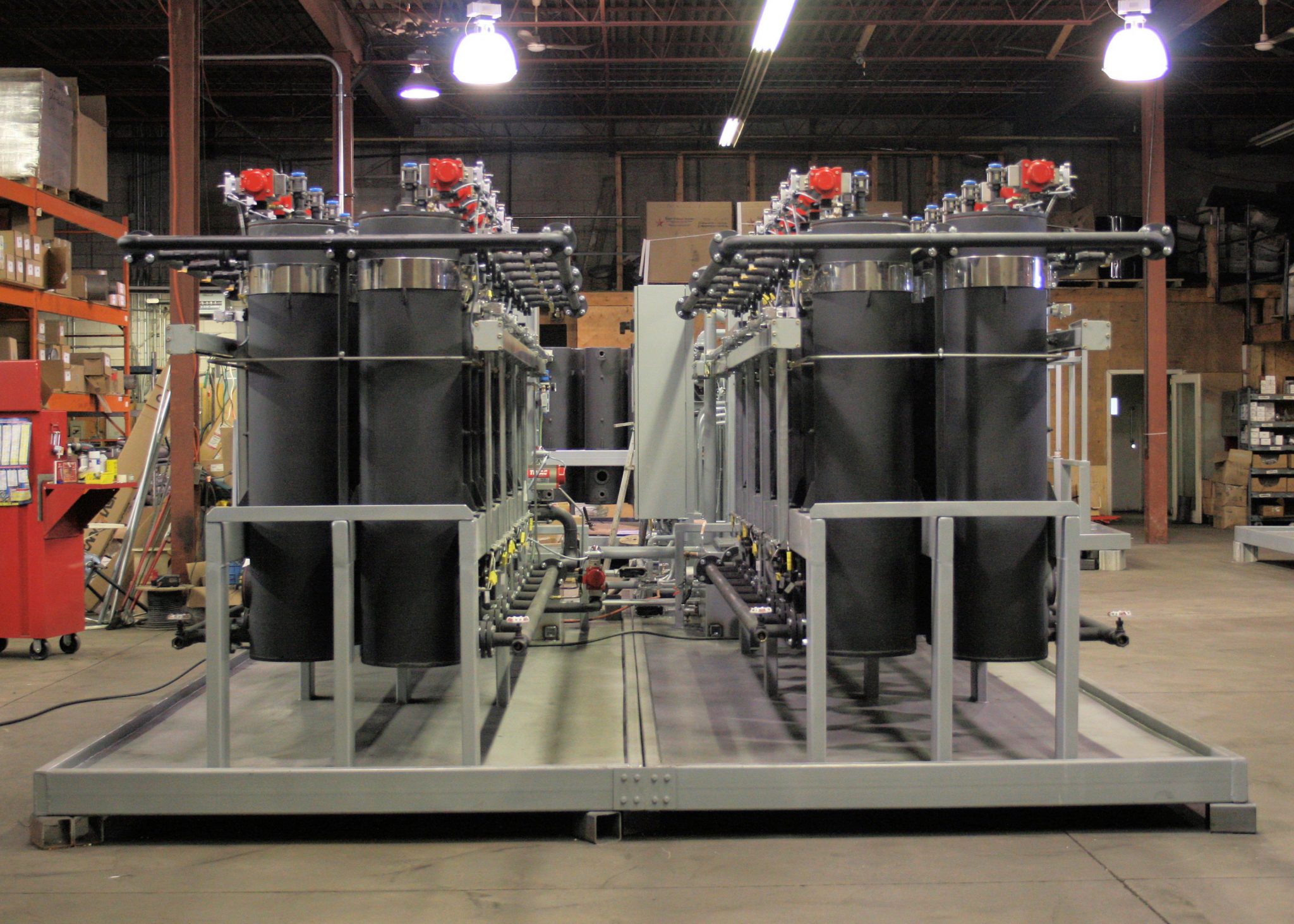

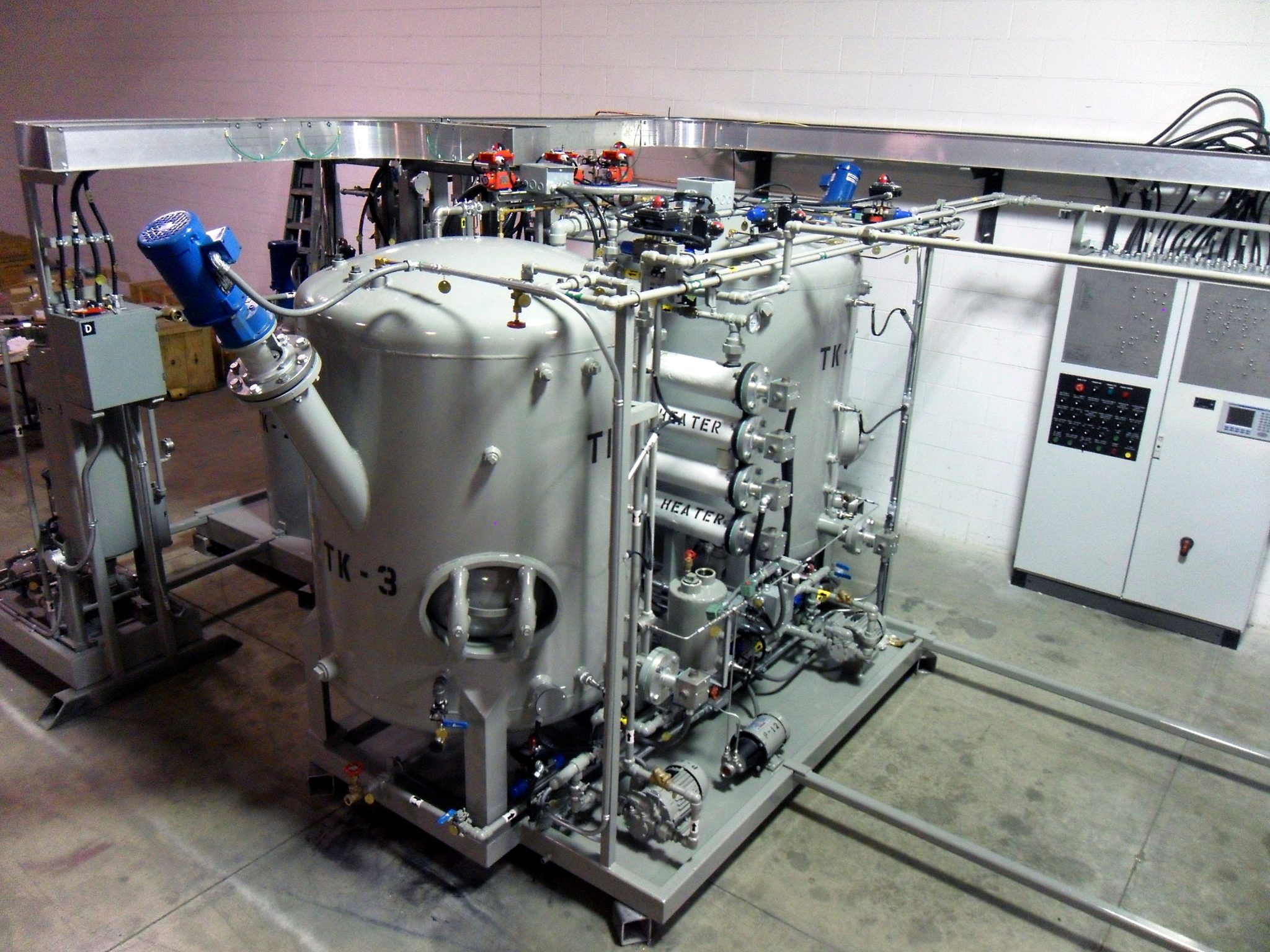

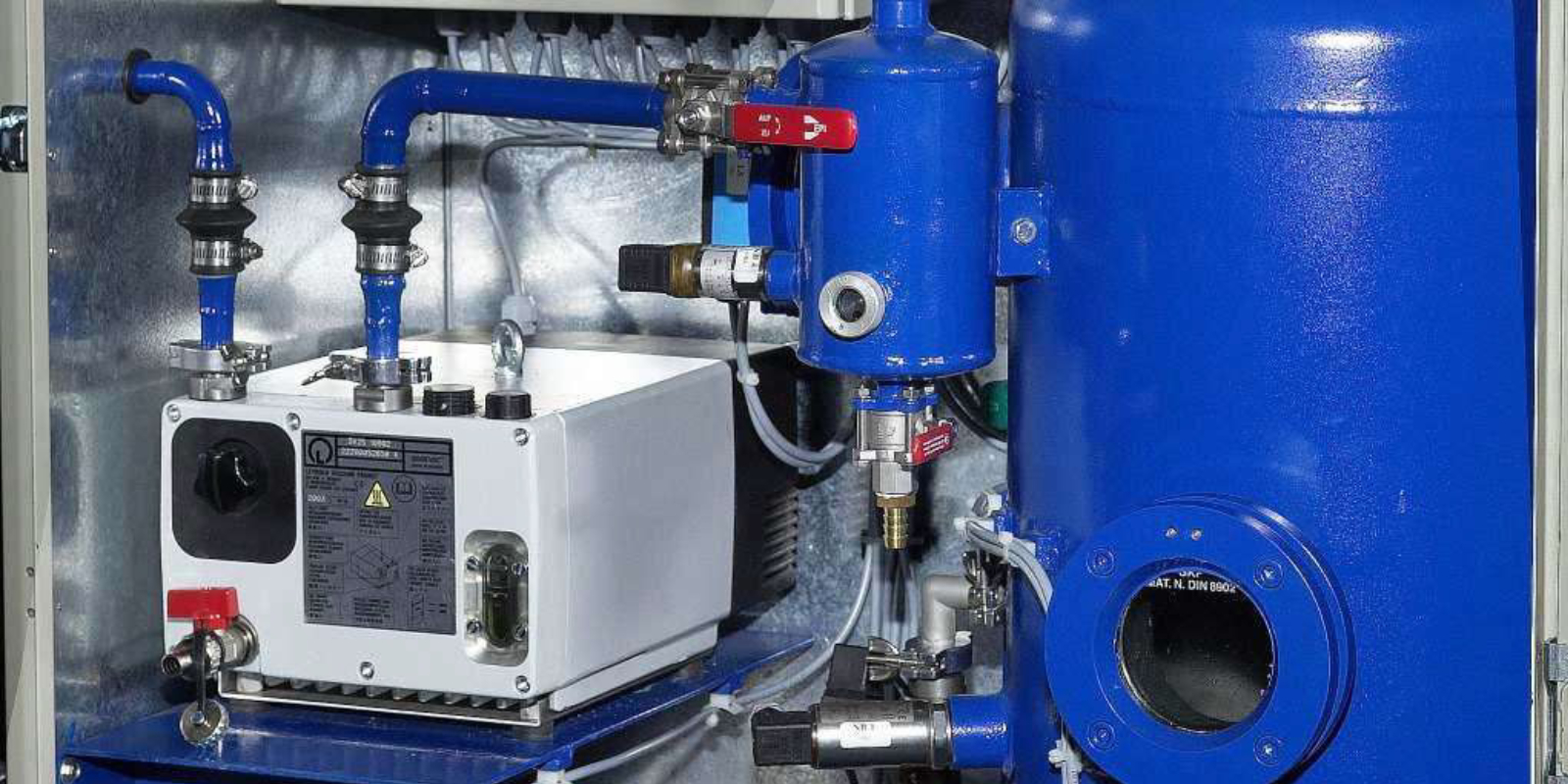

The equipment of the HERING AMPS is based on the proven technology of the HERING RCPS. The HERING AMPS lube oil post-processing plant uses several banks of active columns containing the HERING PHÖNIX GREEN environmentally friendly adsorbent mineral. The HERING PHÖNIX GREEN is a naturally occurring mineral that has been improved in a physical process to yield higher adsorbency performance. The special processing of the mineral ensure that its properties are comparable to that of acid-activated clay, but without the environmental problems of using these chemically activated clays. The initial thermo-physical treatment of the HERING PHÖNIX GREEN ensures that it can be reactivated by our re-refined oil polishing system. You can, therefore, reuse the HERING PHÖNIX GREEN for several hundred cycles before it needs to be replaced. This results in operating cost advantages compared to conventional bleaching clay finishing treatments. In addition, the used mineral of our AMPS is environmentally safe and can be disposed at a conventional landfill after its lifetime. This makes the AMPS the most environmentally friendly lube oil post-processing treatment. For those that are rather looking for a clay based base oil finishing treatment, the HERING RCPS reactivation clay polishing system is the right choice.

The HERING AMPS re-refined oil polishing system can treat oil flow rates up to 27,000 liters per hour

The HERING AMPS natural regenerative media polishing system can be supplied in oil processing capacities ranging from 50 liters per hour to 27,000 liters per hour. The AMPS is especially suited for medium capacity plants that operate under strict environmental legislation. Our lube oil enhancement process is as an excellent alternative to hydrotreating systems for lube oil finishing treatment. We can supply our HERING AMPS re-refined oil finishing treatment plant either in conjunction with a non-cracking evaporator front-end as our HERING WORP waste oil recycling plant or as an add-on or retrofit to an existing re-refining plant. The HERING AMPS natural regenerative media polishing system is perfectly suited to substitute clay-based treatments and old acid-clay processes. We can customize the HERING AMPS layout to seamlessly replace your current acid-clay treatment with our modern lube oil finishing treatment.

ADSORBENT MINERAL POLISHING SYSTEM

The system is especially effective on undesirable polar components within the oil. The AMPS® has the ability to eliminate sulfur from 2000 PPM to less than 300 PPM in a single pass. Processing oil through the AMPS results in an oil that is stable against oxidation over any measured timescale – this increase in shelf-life is an added benefit of the reactivation clay polishing system. The Viscosity Index is not degraded by the clay polishing system so if a Group II oil is fed into the system, then the AMPS® will produce an enhanced Group II oil at the outlet.

The AMPS will process light or medium lube oil, 150N, and will improve the colour to an average better than Saybolt +16. Odour is reduced to non-detectable/barely detectable. Sulfur is reduced from 2000 PPM to > 300PPM. All specifications are input oil dependent. The AMPS is capable of any throughput on a continuous basis. There is an option to increase the throughput provided that the Upgrade Option is selected at the time of order. The system will also process 220SN but at a lesser throughput. Extra processing time may be needed, and this product will have to be heated to reduce viscosity. Reactivation time per bank is also expected to increase with this stream.

- Polishing your high viscosity oil distillates with the AMPS® Series provides you with:

- Low operating costs and initial capital investments compared to other finishing treatments.

- Flexible operating modes – Parallel mode operation is single-pass, least contact time, fastest processing. Series mode operation simulates triple-pass, most contact time, better quality oil.

- Modular system ensures flexible layouts while all modules can be shipped inside a 40-foot high cube container for reduced shipping and handling costs.

- Full client involvement during the manufacture, from engineering approval through to start-up.

- Dual gas scrubber allows for integration of exhaust into front-end refinery to minimize points of emission for environmental permit.

- All global voltages and frequencies available.

- Low oil losses as part of waste becomes feedstock for front-end refinery.

- All waste created by AMPS® is classified as standard industrial waste leading to low environmental costs.

HERING Systems are remarkable for their efficient and robust design, as well as their ease of operation and maintenance. We install only high quality components from Germany, respected Western European & Northern American brand manufacturers. Our systems are designed for long lifetime, reliability and effective operation. Each plant is custom-made and delivered with all required aggregates to leave nothing to be desired. Together, we will develop the perfect solution for you and your company. We are looking forward to serving you!